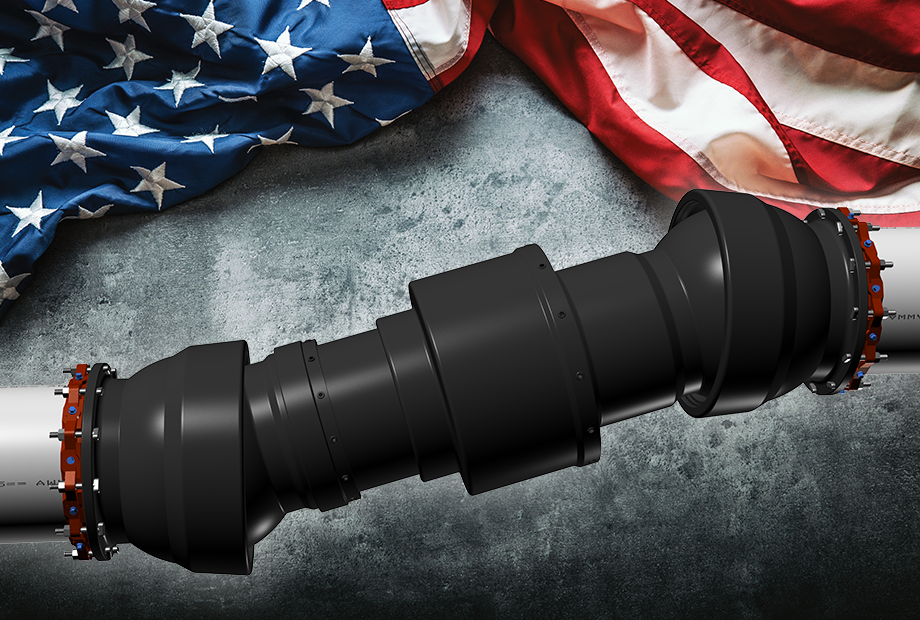

FLEX-TEND® Installation

The FLEX-TEND family of products is a very versatile product line that allows designers to place pipeline connection protection into locations that are subjected to settlement, frost heave, seismic activity, thermal changes, and many other situations. One of the most frequent questions that arises with the implementation of these products is how should they be installed. There are several considerations that go into answering this question and this spotlight will highlight several of them.

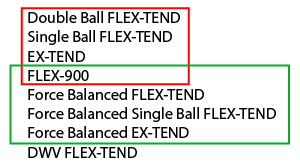

There are many variations of the FLEX-TEND family of products. The variations have different protection capabilities, and the designer needs to carefully consider what kind of differential motion could occur

- Double Ball FLEX-TEND (FT)

- Single Ball FLEX-TEND (SBFT)

- EX-TEND® (ET)

- FLEX-900® (Flex-900)

- Force Balanced FLEX-TEND® (FBFT)

- Force Balanced Single Ball FLEX-TEND (FBSBFT)

- Force Balanced EX-TEND® (FBET)

- DWV FLEX-TEND® (DWVFT)

Best Location

The best location for the FLEX-TEND product to be installed is as close to the point of maximum differential motion as possible. This is, often times, as a pipe leaves a structure and enters the soil or as the pipe transitions between two structures. It is also important that one end of the unit is supported by the structure that will move in one direction and the other end of the unit supported by the soil or structure that will move in the other direction.

Thrust Force

One very important thing that must be considered is the thrust force that is generated when a standard FLEX-TEND is pressurized (see table above). Below ground installations often have the benefit of soil friction to hold that thrust force in check. However, above ground installations, especially if fittings are involved, can be damaged if this thrust force is not accommodated in some manner. This force is generated at the expansion joint of the FLEX-TEND or Ex-Tend (like all conventional expansion joints) and simply restraining the pipe joints does not keep this force in check.

| Product | Offset | Expansion | Deflection | Thrust Force |

|---|---|---|---|---|

| FT | Yes | Yes | Yes | Yes |

| SBFT | No | Yes | Yes | Yes |

| ET | No | Yes | No | Yes |

| FLEX-900 | No | No | Yes | No |

| FBFT | Yes | Yes | Yes | No |

| FBSBFT | No | Yes | Yes | No |

| FBET | No | Yes | No | No |

| DWVFT | Yes | Yes | Yes | N/A |

For waterlines, use of the Force Balanced FLEX-TEND will eliminate the thrust force at the expansion joint and simplify the design and future function of the pipeline.

Find out more about thrust force by reading the following Connections Bulletins: FT-04 How does the Force Balanced FLEX-TEND® Product Work? and FT-05 Bridge Crossings and The Proper use of EX-TEND, FLEX-TEND

While FT-05 address bridge crossings the concepts described can be applied to many different, above ground applications.

Important note- DO NOT use standard FLEX-TEND family units in the same pipeline with Force Balanced FLEX-TEND family units. The Force Balanced units are thrust neutral and the thrust that develops at the standard unit will cause the Force Balanced unit to compress. The units in the red box can be used together and the units in the green box can be used together. Here are the units that can be used in the same pipeline. The units in the red box and the units in the green box are force balanced units.

Connecting Pipeing

The pipe connected to the FLEX-TEND unit must be restrained, and it must be strong enough to transfer differential motion to the FLEX-TEND so that it can protect the piping as intended.

It must be restrained. It does absolutely no good for the FLEX-TEND to be in place if the differential motion causes an unrestrained pipe joint to separate. How much of the piping must be restrained? It is totally dependent upon how much piping is subject to the differential motion. Once the piping is well away from that area it can be possible to switch to unrestrained pipe.

Especially for above ground piping, when using factory installed restrained joint pipe, be sure to pull any slack out of the joint before pressurizing as instructed by the pipe manufacturers. Like the standard FLEX-TEND, the slack in a restrained joint is an unrestrained joint until the restraint is fully engaged. As such it will exert a thrust force that can cause a multitude of problems.

If the piping is not strong or stiff enough to transfer motion to the FLEX-TEND it is possible for the piping to break or collapse. Again, if this occurs the FLEX-TEND will not be able to protect the pipeline connection as intended.

You can find out more about what kind of piping is and isn’t appropriate by reading the FLEX-TEND Installation Instructions. The FLEX-TEND Torque Curves show the moment loads required to cause the ball joint components of the FLEX-TEND to deflect.

Buried Applications

FLEX-TEND products can be used in buried applications. It must be remembered that the FLEX-TEND is most effective in protecting connections from damage as a result of differential motion when it is most free to move. It is for this reason that the backfill around a FLEX-TEND should be as loose as possible and that friction from the backfill material be as small as possible.

As an extreme example, if the FLEX-TEND is encased in concrete the unit will be fine, but it will not be able to move and protect. The same reasoning applies to high compaction of the soil. The designer must determine what an appropriate compaction should be based on the specifics of the application.

Regarding friction, a good low friction backfill material is pea gravel. Also, every FLEX-TEND unit is shipped with a polyethylene sleeve. Installing this sleeve also helps to reduce the friction acting on the unit and provides more freedom for the unit to move and protect.

Deep Bury Applications

Will FLEX-TEND units be damaged in deep bury applications? There is a simple answer, but the answer is really much more involved.

The simple answer is that the soil compaction resulting from the deep bury will not damage the FLEX-TEND unit in the same way that it will not damage fittings used along the pipeline.

The involved answer is that it is important to remember why the FLEX-TEND is being used. It is being used to provide strain relief for connections that will be subjected to differential motion. If the connection is subjected to high soil compaction, can the FLEX-TEND move and protect in response to the differential motion? The FLEX-TEND is best able to protect a pipeline connection when 1) it is free to move, 2) it is connected to a restrained pipeline so that all movement of that pipeline can be transferred to the FLEX-TEND, and 3) it is placed at (or as near as physically possible) to the point maximum differential motion.

It has been suggested that a way to remove the soil load is to place the unit in a vault. This can be done but the designer must make sure that the pipe openings for the vault are large enough to accommodate the anticipated differential motion. If the openings are too small then the units cannot move as needed.

Above-Ground Applications

As mentioned above, the more freedom that a FLEX-TEND unit has to move the better able it is to provide the intended protection. As a result, an above ground installation should be most free to move. This is not the case, however, if bracing used to support the unit and/or connected piping limit the ability to move. This also is not the case, for example, if the unit is placed right against a wall and is therefore limited in its ability to travel in one direction and the intention is for protection against differential motions in every direction is intended.

Lateral support for exposed pipelines (think bridge crossings) is very important. Simply supporting the pipe vertically is not enough. If the pipeline starts to move and there is no lateral support the pipeline could deflect to the side and never transmit the movement to the product that is intended to provide protection. Remember, the goal is always to force differential motion to the FLEX-TEND so that it can provide strain relief and protect the pipeline connection.

This is one more reason to feel comfortable relying on EBAA Iron products, and specifically EBAA Iron Flex-Tends, in your system.

Product Page