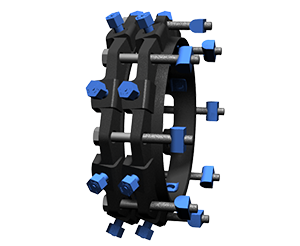

1100 MEGALUG®

MEGALUG® Mechanical Joint Restraint

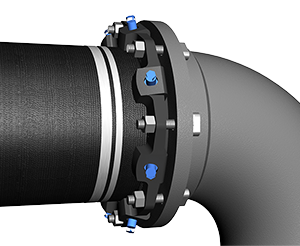

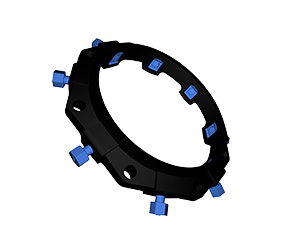

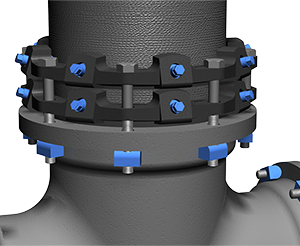

The Series 1100 MEGALUG® Mechanical Joint Restraints effectively and economically restrain Ductile Iron Pipe (DIP) to mechanical joints above or below ground, for practically any application including valves, hydrants, and pipe. For use on all classes of ductile iron pipe (PC350 through PC150 and CL56 through CL50) without damage to the pipe or cement linings. It can also be used on steel pipe and cast iron pipe when joining to mechanical appurtenances, see product brochure for more details on these pipes.

Available in sizes 3 inch through 60 inch.